Pad Printing: Precision Branding on Any Surface

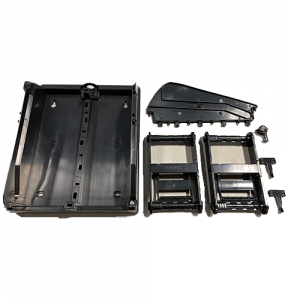

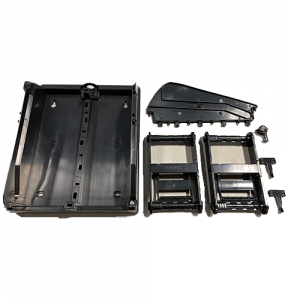

Unlock the power of pad printing—an innovative solution for applying crisp, detailed images to products with curves, contours, and complex shapes. Using a flexible silicone pad, this highly adaptable process transfers artwork from a laser-etched plate directly onto three-dimensional, recessed, or irregular surfaces with exceptional accuracy.

Perfect for logos, labels, and fine details, pad printing enhances your product’s appearance while maintaining consistency across a wide range of materials. Whether you’re branding promotional items, medical components, or industrial parts, pad printing delivers professional, high-quality results where other methods can’t.

When your product shape is anything but flat, pad printing is the perfect fit.